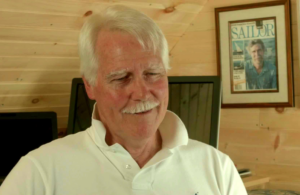

John Patnovic grabbed some headlines about a year ago for rescuing Post Yachts from bankruptcy, but his resume also includes some impressive accomplishments. The 65-year-old’s Bertram 31 remanufacturing program has transformed eight old boats into refurbished icons. Patnovic and his wife, Libby, own and operate Worton Creek Marina in Chestertown, Md., which has been servicing, maintaining, repairing and retrofitting boats since 1949 (www.wortoncreek.com).

Reviving Post has been tough. Since acquiring the company in late 2011, Patnovic’s Post Marine Group has yet to sell or build a Post. But Patnovic says he is “in this thing for the long haul.” He has the molds to build six models from 42 to 66 feet, and he wants to expand the Post fleet with larger boats (www.postyacht.com).

Patnovic grew up boating with two uncles on upper Chesapeake Bay and has owned boats from 25 to 91 feet, including two wooden Chris-Crafts. He loves to work on boats as much as he enjoys running them. His current boat — a 1990 91-foot fire-damaged Burger — still needs work, but Patnovic uses it periodically.

Worton Creek Marina has a staff of 18 employees. Patnovic plans to work in the boatyard until “I keel over in it.” One of his three daughters, Martha Callahan, is the part-time controller for Post, and her husband, Patrick Callahan, has full-time duties managing manufacturing and information technology. Patnovic’s wife manages office operations and keeps the books.

Patnovic and his wife live a stone’s throw from the boatyard. Besides boating, he likes classic automobiles — he has a 1955 Chevy and a 1965 Corvette — and model building.

Q: Before we get started with the Post story, describe how you rebuild the Bertrams.

A: We take old 31 Bertrams and gut them, so all we have left is the fiberglass components, and then we rebuild the boat from there. Our niche with the 31s is delivering a boat built to far higher standards than when it left the factory and designed to reflect the owner’s intended use, from fishing to evening cocktail cruises. They are totally remanufactured — new windows, running gear, engines, wiring, interior, you name it. The boats leave here with a price of $300,000 and up. We started our ninth retrofit, with delivery scheduled in late fall 2014.

Q: What has happened since you acquired Post Yachts in late 2011?

A: We moved the whole operation from Mays Landing, N.J., to our facility in Chestertown, Md., on the Upper Eastern Shore of Chesapeake Bay. We are restyling the boats to modernize their lines while retaining the Post look. We are also digitizing our molds so we can design using 3-D.

Q: It must be disappointing that you have yet to sell a boat.

A: I didn’t anticipate that the economic recovery would take so long. Our size range is 42 to 66 feet, and this midrange segment is still pretty dead. Boats 75 feet and larger are selling, and the center consoles of 35 feet and smaller are selling. Our traditional customer has been the small-business owner, and right now most of them are in a holding pattern, waiting to see more of a recovery and waiting to see what’s coming out of Washington. As a small-business owner myself, I can tell you that our concerns about stifling regulation, health care, the state of the economy and the anti-business atmosphere are making us look very carefully at what we are spending.

Q: Do you have any used Post yachts on site?

A: We have five Posts in the yard this winter for work ranging from gelcoat repair, teak coaming work and deck replacement to extensive interior upgrades. We will build new Posts, maintain and refit older Posts, and offer brokerage services, as well.

Q: How have you promoted the brand?

A: We’re attending boat shows in Annapolis, Fort Lauderdale and Miami. And we’re doing some media advertising and have a good Internet presence.

Q: What is your sales pitch?

A: We will build you a state-of-the-art, semi-custom boat with a good turn of speed. She will be laid out and equipped to reflect your boating lifestyle. We are committed to making the building experience pleasurable and satisfying. You will be dealt with honestly and with respect.

Q: What was your thinking in acquiring Post Yachts?

A: The owner had decided to close up shop. I went to look at their teak inventory. I bought the teak and eventually bought the company. I have a substantial boatyard operation with highly skilled people. We can do anything on a boat with in-house personnel except for upholstery, which we subcontract. I felt that acquiring Post would be a good way to expand our business. I think a small, low-overhead semi-custom boatbuilding operation with boats at a reasonable price will be a player.

People with a passion for boats run most of the successful boat companies. If I wanted to make a lot of money I would not be in the boat business. I definitely have a passion for boats — a passion that’ll transfer to the boats we build and the way we treat our customers.

Q: With a few years under your belt, do you think you would do it all over again?

A: Most definitely. I just didn’t anticipate the agonizingly slow pace of our recovery. And I didn’t think the discord in Washington would continue as long as it has. I have great confidence in the American economy and in our business plan, and we’re in this long-term. So would I do it again tomorrow? Absolutely.

Q: You’re 65. How long will you continue working?

A: I would like to be like Jarvis Barton of Portland Boat Works in Connecticut. He was 91 years old and still at work every day. He passed away at the boatyard one day. That’s how I would like to do it.

Q: What has been your biggest challenge since acquiring Post?

A: The economy. Our second-biggest challenge is to find the person who will buy the first boat. Most people want to see and touch a real boat. We have to find a buyer who has the confidence in us to order the first boat without a sample. We have considered building a spec boat, but my gut says this is not the right time. As the economy improves, we will revisit this option.

Q: What are your goals for Post?

A: The No. 1 goal is to sell the first boat [chuckles], and part of that is re-establishing the brand. When we first started doing the boat shows, people came up and would say, “I thought you were out of business.” Now people know we are up and running and want to know how we’re doing. We’re getting the word out that we are still in existence and ready to build boats.

A longer-term goal is to move into larger boats. Our biggest model is a 66-footer. I would like to move up to the 75-foot range.

Q: What kind of boatbuilding materials and processes will you use?

A: We have molds to build a 42, 47, 50, 53, 56 and 66. These are convertible-style boats. We also make a 42 and 53 open or express-style. We will use resin-infusion with foam coring for the hull construction and major components. We will make extensive use of 3-D CAD to design and model the boats. This enables us to offer the semicustom aspect efficiently. It gives us the ability to give the boater exactly what he or she envisions in terms of interior layout and design. The beauty of using 3-D CAD is we can go straight from the design on the computer to computerized routers to cut the parts.

Naval architect Lou Codega will be helping us with naval architecture, design and engineering. He will work with us on weight distribution, center of gravity and other engineering factors. Lou had a lot to do with the design of the 66.

Our interior cabinetry will be built by Larry Belkov of Belkov Yacht Co. in Annapolis, Md. Larry specializes in high-quality custom yacht interiors and can provide the quality and craftsmanship we want.

Q: How long will it take to build a Post?

A: It will take one year for all of the models, except for the biggest. The 66 will take 18 months.

Q: What is your boatbuilding philosophy?

A: I like boats that are light, fast, rugged and kept simple. The trend today is toward fitting as many bells and whistles as you can in a boat, and we are capable of doing that. The downside is that if a particular system fails, it can shut down the whole boat. If you are offshore in 10-foot seas you need to be able to troubleshoot and repair things quickly. With a lot of the computerized systems in use, you need a skilled technician to figure out a problem. So if you go with a lot of sophistication, I would want manual overrides on critical items like bilge pumps, fire suppression systems, running lights, etc.

We will pay a lot of attention to equipment placement and accessibility. We work on a lot of different boats, and many of them were not built with maintenance and repair in mind. We had a 50-foot motor-yacht, and to get to the head system you had to climb over the engine. So whenever we work on that boat I have to have two people there — one to climb over the engine and the other to hand that person parts and tools. The owner of the boat always goes nuts on me because it costs so much.

Q: Tell us about your lineup — the Post brand?

A: The brand and boats are pretty much the same. Posts have been used as tournament fishing boats, as pure cruising boats, and combinations of fishing and cruising. Post has a reputation for building rugged, fast semicustom boats with nice interiors. We will continue in that tradition while upgrading the lines of the boats and going for knockout interiors.

Q: What is your professional background?

A: Many lives ago, I was a mechanical engineer. I ended up as part of an investment group that did start-ups and turnarounds of small to medium-size manufacturing companies. I specialized in company operations, sales and marketing.

Q: How did you get into boating?

A: When I was a young boy, two of my uncles had boats. One had a 36-foot Colonial, and the other had a 25-foot Trojan. I started boating with them. For me, it was love at first sight. I took to it like a duck to water. And I have been messing around with boats ever since. My first trip on a boat — I was probably 9 years old — was on the Colonial on the Chesapeake Bay. My early boating was on Chesapeake Bay and [in] New England.

Q: What do you most like about boating?

A: My favorite part is being out there in the early morning or evening. Plus, I really love to work on boats. The very concept of a recreational boat intrigues me; they’re tidy packages of systems that provide a living space that you can move on the water. I’m not quite sure why being on a boat is just magic for me. I can have the worst day at work imaginable, but when I step aboard my boat the bad day melts away and things get back in perspective.

Q: What are some of the boats you have owned?

A: We started with a 27-foot wooden Chris-Craft, and then we went to a 42-foot wooden Chris-Craft, and then a 50-foot Hatteras motoryacht and a 70-foot Hatteras motoryacht. Now we have a 91-foot Burger. All of these boats have been projects.

Q: Today’s center consoles are nearly 50 feet. Does this concern you, that people might be losing interest in convertibles?

A: I think the center consoles are appealing to some people. They are fast and more fuel-efficient than the big battlewagons. But at the end of the day they are primarily dayboats, and our segment of the market will continue to want the amenities of a convertible.

Q: What do you think of the latest navigation technology, such as joysticks?

A: I am embracing the technology. We have the capability, through Caterpillar and ZF Marine, to bring joystick technology to our conventional shaft-drive inboard yachts.

Q: Will customers opt for this?

A: I suspect they will. The joystick control makes handling the boat a lot easier. I guess I’m too old-school. To me, a lot of the fun of boating is developing the skills to handle the boat well. I think you miss part of the experience if you have an over-dependence on the joystick.

March 2014 issue