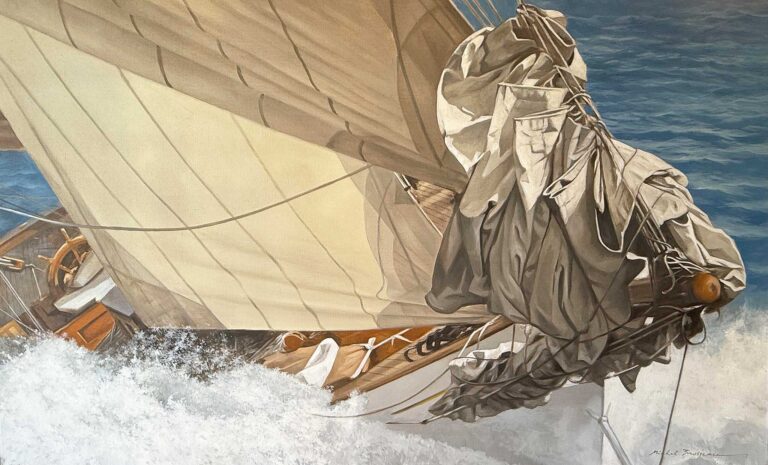

Sideways is not a direction that anybody involved with a refit wants to see things go. But it’s a reality on many projects, with all kinds of boats that owners are looking to upgrade in small and large ways. According to experts from three of Maine’s top yards—Lyman-Morse, Front Street Shipyard and Brooklin Boat Yard—problems tend to happen for reasons that can be avoided by working smarter with a better facility from the get-go.

“It’s very important to build a relationship with the yard that’s doing the work,” says Eric Beckman, service manager for the Lyman-Morse yard in Thomaston. “That’s not for everyone. They may say, ‘Here’s the list, we’ll see you in August,’ and that’s fine, but if you take a vested interest in the work, it’s better.”

Here’s what Beckman and other experts say are the best ways to avoid problems, whether the plan is for a cosmetic upgrade or a complete overhaul of a boat.

Shop Around

Choosing the right yard is the first priority. The idea isn’t just to find a yard that is capable of the job, but instead to find a yard that is both capable and comfortable.

“Visit these yards in person,” says Nick Bellico, service manager at Brooklin Boat Yard. “Just walk around. That will tell you a lot about how that operation is going to go. If you can meet with people, shake hands and see the facility and the crew working on the floor, you can get a pretty good sense of morale, ethics and communication.” By contrast, Bellico says, “If you walk into a yard and are shoved into an office and only allowed to talk to one person, that’s a little telling, that you’re not going to be prioritized.”

JB Turner, president of Front Street Shipyard, says boat owners can narrow down their list of preferred yards on paper and then visit a handful before deciding. “Shopping more than five yards gets confusing,” Turner says, “but two or three that are well-known, that’s what I would do.”

Some of the better shipyards will compete to win work on 40- to 60-foot boats, Beckman says. When boats get larger, the yard needs a dedicated team on the project. Midrange boats can make use of the whole yard and its various departments. “If it’s a 50- or 60-footer, that boat is not as constrained by overhead clearances or beam issues,” Beckman says. “They can use multiple places in the yard to do what that boat needs.”

Have “The Talk” Early

After choosing a shipyard, the next step should be an in-depth conversation about prior boating experience, future goals and money.

“Generally, my first question (allows me to) get to know the person,” Bellico says. “Are you a day cruiser who goes out for picnics? Are you a coastal cruiser who goes offshore? Are kids on the boat, and is safety a concern? That will lead to an idea of the scope-use profile of the boat, which then, I try to put a gauge of cost in front of the owner pretty immediately.”

Bellico says another crucial point that should come up early is that a refit is not an investment. “It’s never an investment, and I always make that clear upfront,” he says. “You’re not refitting a boat to sell it next year and get your money back. That’s not how this works.”

Turner says he tells boat owners the same thing: “Boats are not appreciating assets. The money you put in, you’re not going to get back. If you want to keep the boat for 10 or 15 years, and you love boating or sailing, then it’s worth it. But being under the delusion that you’re going to get your money back when you sell it is not going to happen.”

Beckman also says it’s paramount for money to be part of the conversation early, even if the shipyard is only providing a round number at the start. “It just feels a little bait-and-switchy when that conversation doesn’t happen,” he says. “If you don’t have at least a cursory conversation about the finance part of it, you’re not setting yourself up for success. You don’t want the client to commit and have this work order blowing up. Both parties have to know what we’re getting into.”

Expect the Unexpected

Wish lists are great to start with, all three yards say, but realistic to-do lists with financial cushions are far more likely to result in a successful refit experience. “There’s always going to be something that comes up,” Turner says. “Your budget should have an extra 10 percent or 15 percent. You’re going to have other things happen.”

Bellico recommends building in 10 to 20 percent above the initial estimate: “This is, at the end of the day, custom work. If you’re going to change the engines, you’ll run into something with carpentry or paint or electrical in that area. There’s a domino effect of things you cannot know until you start the job.”

Beckman says that as problems are found, owners are sometimes surprised by what it might take to fix them. Failing to heed a yard’s warnings at those times can lead to extra costs. “There have been some situations, particularly mechanically, where we’ll have to remove something, we’ll have to take something apart to diagnose or fix or troubleshoot,” he says. “You have the conversation ahead of time that it might not be able to go back together the same way, so we recommend replace. We try to put that in their brain, that it’s probably more cost effective sometimes to replace.”

A common mistake that boaters make is to insist on attempting a repair first. Oftentimes, the boat owner ends up paying for the attempted repair and the replacement. “It’s not a perfect world, after all,” Beckman says. “There are times when it does work out, but we try to identify when that’s not a good path to go down.”

Communicate Constantly

One of the best ways to avoid surprises, all three yards say, is to be involved with the process. Be available by phone, email or text. Drop by the shipyard frequently. “Don’t be afraid to check in,” Beckman says. “You’re giving your property—one of your most favorite activities—you’re entrusting it with us. You should never feel as if you can’t contact the manager or the yard directly.”

Owners being involved is actually better for the shipyard, he adds: “It’s much easier, if something comes up, to be able to text or Facetime an owner and say, ‘These two samples came in, can we look real quick?’”

Being around the yard will also help boat owners understand what’s actually being done, Beckman says. For instance, with paint or teak decks, the biggest expense tends to be not paint or teak, but instead deck hardware removal and reinstallation. “The best way to do it is to pull every piece of hardware off, because the more you tape around that stuff, you’re getting hard paint lines that are a possible failure point,” he says. “People will say, ‘Hey, the teak is only $100,000.’ But it’s going to take 300 hours to take it off, and another 500 hours to put it back on, because it all goes back on with new bedding compounds and fasteners.”

Bellico says that for many boat owners, being involved becomes a learning process that makes them better boaters in the long run. “The more visits you make, the more informed you are about the project, and when it’s done and you’re ready to use the boat, you know how things work because you were involved with the process the whole way through,” he says.

About half the owners who choose Brooklin Boat Yard do in-person visits, Bellico says. About 70 percent communicate regularly throughout the refit process. Still, Turner says, if communication with any shipyard goes south, boat owners have every right to stop the work and get another opinion. “Let’s say the yard goes way outboard of its estimate, or starts to do crummy work, that can be really bad,” he says. “I would stop and bring in a surveyor to ask, ‘What’s going on here?’ You can bring in an expert at any time.”

And even if everything goes swimmingly, he adds, smart owners stay near the shipyard after the refit is complete—just in case additional problems crop up. “Launching and going away usually goes badly,” Turner says. “Stay in the area for a few weeks after launching the boat. Cruise around the area so you’ll find the bugs. Once you go away, it just makes it difficult for you or them to sort out any issues.”

January 2025