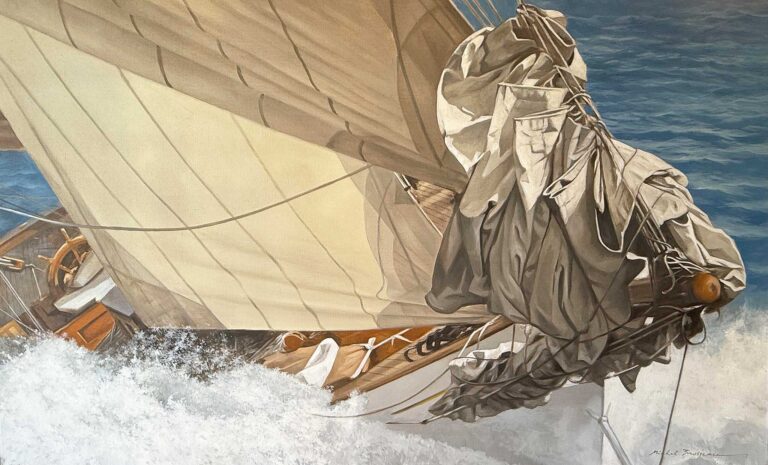

If Aristotle was right, there is a foolish corner in the brain of the wisest man. And if he had known sailors (and how could he not?) he must have observed that owners of wooden ships must have an especially large cerebral portion set aside for foolishness — because they are forever fiddling, sanding, painting and caulking. And when the yacht finally is shipshape, they quickly think of something else. Like building a wooden tender. It doesn’t get any more foolish than that. Or does it?

“There is nothing like a sailing dinghy to make a man of [a boy],” observed L. Francis Herreshoff. “He will learn an appreciation of property and a sense of responsibility (for the dinghy is easily damaged). He will learn to be a good sportsman and take his lickings, wettings and bumps perhaps more cheerfully than in any other way.”

Good old L. Francis. Never short on opinion, he saw a higher purpose even in the smallest of boats. But looking at the old drawings of stout little dinghies, such as his H-14, one can understand why.

By contrast, modern towable and stowable tenders are boring commodities. Often aesthetically challenged, they are designed for the mundane job of shuttling crew between boat and dock. People buy them like shoe polish or a toothbrush. It’s about practical value and cost benefit, but rarely about a higher purpose.

Weight, measurements and carrying capacity are determinants that favor inflatables that are stable and easy to pack. Or light fiberglass boats. Or clunky ones from rotomolded polyethylene that are maintenance-free and can be recycled at the end of their useful lives — in theory, at least.

If this trend is right, classic wooden tenders are following woolly mammoths and saber-toothed tigers into extinction. I harbor no doubt that this will happen eventually, but we’re not there yet, as I learned when I started rooting around for those foolish folks who fire up a table saw and skilfully wield a plane to fashion something from scratch: a stubby little boat with lapstrake planks; a springy sheer with a fat, three-stranded rope; a pair of bronze oarlocks; and a cute name.

Concordia’s dinghy legacy

Some of the most ardent acolytes of wooden-dinghy culture can be found among the owners of Concordia yawls — the classic sailing yachts designed by C. Raymond Hunt and built in Germany (for the most part) by the Abeking & Rasmussen yard, near Bremen. Along with those sleek yachts, which are known for their sailing qualities as much as their pleasant appearance, A&R often delivered so-called Bateka dinghies — little prams that were used as tenders and towed or, on rare occasions, stowed on the coach roof. They were built to plans from the Concordia Co., then in Padanaram, Massachusetts, which sold them to U.S. customers.

Legend has it that these Batekas were built by German apprentices to showcase their skills. Boats that passed muster were sold to customers; those that didn’t became incense before the assembled crew. I’d take this yarn with a few grains of salt, but knowing the old customs of European apprenticeship culture, it’s not entirely out of the question.

One that met the masters’ expectations — and was therefore endowed with an A&R brass plaque, showing build No. 4,981 from 1954 — now belongs to Doug Adkins, an investment banker who lives in Seattle. He unearthed it in a barn in Maine and had it trucked across the country and restored to the nines before relaunching it at Jensen Motorboat Co. on Seattle’s Portage Bay. Because he also owns the varnished Concordia yawl Coriolis, he christened the tender Perigee to stick with the celestial theme. It was a grandiose tongue-in-cheek affair when that 8-foot Bateka, with her gold-lettered name on the stern, rumbled down the ways, fully dressed. And when the music stopped, the fun began, just not for Adkins.

“She leaked like a sieve,” he laughs, recalling the moment when he tried to row her the short distance to the club, with so much water sloshing around his ankles that he had to abandon the effort. He repaid her seams and took her to his summer house in West Sound on Orcas Island, where Coriolis tugs on a mooring. “Perigee is a fine little boat. She’s lovely and stable but too heavy for everyday use,” Adkins says. So why not stick with a small RIB or a little production boat like the Dyer dink? “It’s wonderful for show,” Adkins admits.

It’s like good cooking

An original Bateka also proved to be the undoing of Jeff Makholm, a Boston-based economist who owns the Concordia yawl Arapaho. He talked about wanting to build his own dinghy from scratch, and before he knew it he was quoted in the class newsletter, putting him on the spot. “They didn’t look too complicated, and I thought I could tackle such a project,” he says. “The more I looked into it, the more complicated it became.”

Not to be deterred, he obtained the 1950 plans from Mystic Seaport Museum, which keeps Concordia’s historical records. Then he converted the family room in his townhouse into a boat shop and set to work. It took about half a year, lightning-fast for a weekend warrior. What helped him, aside from focus and determination, was humor. “Lofting was hard, riveting was tedious, and varnishing was a pain in the butt,” he says.

To fill in the blanks, he read WoodenBoat magazine and books by Howard Chapelle and Bud Mcintosh. “I planked in northern white cedar and used white oak for transom, ribs and gunwales, and mahogany for the thwarts,” Makholm says. And then there was the hackmatack for the knees. “That was tough, had to call a farmer in Nova Scotia.”

Today, Makholm uses his Bateka as his regular tender, not just for kicks. He tows it behind Arapaho but also found a way to hoist it by himself with the main halyard and stow it on the cabin top, upside down. But that’s the just reward on top of reaping intangible benefits from this project: proving to himself, his peers and the class newsletter that he’s not all talk and getting (compensated) help from his teenage son, who backed the 900 rivets. And he relished the intellectual side of the job. Building a little boat from scratch challenges amateurs much more than a pro, who has the subcutaneous savvy that comes with routine and experience. “It was a series of puzzles that had to be figured out,” he recalls. “Conceiving what to fix next with a single malt in hand was the most satisfying part.”

Makholm also draws comparisons to good cooks who try different things, unintimidated by the possibility of failure. And his instructions for the Bateka recipe are quite succinct. “You must enjoy shaping wood. You need a dedicated space and a family who will put up with you. You must overcome your inhibitions.”

Inhibitions about boatbuilding are a thing of the past for Dan Smith, a surgeon who lives in St. John, Missouri — far away from big water — but keeps his Concordia yawl, Eagle, in Islesboro, Maine, for the summer. He’d already built a cedar-strip canoe that resembles furniture and a Herreshoff 12-1/2, which is well above beginner’s level. Smith has his own tricked-out workshop and enlisted help from his two adult sons.

“I wanted to be a purist,” he says. “We use it as a rowing dinghy and enjoy it a lot. It is very comfortable and stable and tows well, with little drag.” Like other do-it-yourselfers, he, too, figured out stuff on his own, such as attaching a rubrail from three-strand rope.

Maybe someone will write a Bateka book for future generations who love to dabble in the past. “Going to [classic yacht] races is like going back 100 years,” says Smith. “And rowing ashore from [Eagle] in a little Bateka just tops it.”

A future for the past?

On the far side of the planet, Jan Vogt, who runs a boatbuilding shop on the Schlei fjord near the German-Danish border, likes to look to the future when he thinks about the past and the merits of small wooden tenders. “Wooden boats that are well built might last for a century or more,” he says. “They can be heirlooms that are passed down from generation to generation.”

At first that sounds incredible, but he makes some pretty good points. Today’s materials and preservation techniques for wood are better than ever, yet boats built 80 or 100 years ago still exist. And prudent use paired with regular maintenance can sustain a wooden boat at least as long as, if not longer than, a plastic tub that becomes landfill or feedstock for pyrolysis if it gets too beat up.

But like a dentist, Vogt keeps drilling until he reaches the root, the emotional level, which is where boat-buying decisions usually are made. “People step onto their yachts to simplify their life and find peace,” he says. “And when they get into a little tender, they take simplification to yet another level. They row out to have a picnic or take a nap. And with a nice boat under their rear end, that just feels right. Honestly, who’d drift around on a rubber boat with a nice glass of wine?”

So was Aristotle correct about the foolish corner in the brain of men who fall for wooden tenders? Yes, when measured by materialistic standards. They are more expensive to build than mass-produced boats. They are heavier than boats made from sandwiched laminate. And they require more TLC than a rotomolded hull. But when intangibles come into play — pride of ownership, admiration of peers, the you-know-what-eating grin that’s brought out by the muffled sound of water lapping against a wooden hull (inside and out), and the contrast of varnished wood against the ocean’s blue — it’s those fools who have the last laugh.

Dieter Loibner is sailing editor for Soundings.

January 2015 issue