As the shipwrights and specialists at Maine’s Brooklin Boat Yard (BBY) buzz around the three boats inside the main shed, one solitary figure remains stationed at the bow of the 49-foot river boat in the middle of the building. Seated on an inverted 5-gallon bucket atop the staging, Reed Hayden steadily pounds away with a mallet and chisel to carve an intricate, incised scroll pattern into the bow.

It may have been commonplace in the Age of Sail to see a man fearlessly driving a sharp chisel into a brand-new hull, but in the 21st century, ship carvers have become a rarity.

Ship carving started thousands of years ago. The ancient Greeks used figureheads on their vessels to symbolize acute vision and ferocity. The Phoenicians used holy birds and horses to provide protection to the vessel and crew, and the Vikings used figureheads to ward off evil spirits. Sailors were a superstitious bunch. Some even viewed the figurehead as a living thing. They believed that a vessel needed eyes on its bows to find its way, and if a figurehead was damaged it was considered a bad omen.

Ship carving reached its most ornate state during the Baroque period from the early 1600s to the mid-1700s, when European East India companies used ornamental wood carvings to show off their financial prowess. Besides figureheads, ships were adorned with nameboards, trailboards, and tafferels that might include the company’s emblem. During this period, carvings could be found almost anywhere on or inside a vessel. Major shipyards would have at least one carver on staff. In the second half of the 19th century, Mystic, Connecticut, had one ship-carving business that serviced most of the six shipyards on the Mystic River.

The development of iron and steel hulls in the mid-1800s gradually put most ship carvers out of business. Today, it’s difficult to find a ship carver in the United States. Reed Hayden is most likely just one of a few.

Hayden says everything he’s done in his life has led to his ship-carving specialty. He grew up on Cape Cod where, as a 12-year-old, he got a job at Baxter Fish-N-Chips, a waterfront seafood joint in Hyannis where he gravitated toward the dock and took in lines from boaters. “That’s where I caught the boat bug,” he says.

He was always interested in art, and took art classes in high school, but he found he was more drawn to building things, which probably runs in his blood. “Most of my family are pipe fitters out of Brockton Local,” he says. As a teenager, he framed houses on the Cape. When he went to college at the University of Massachusetts at Dartmouth, he majored in sculpture and learned welding and woodwork. While attending school, he started working at a sign shop on the Cape in Sandwich. The owner, Doug Amidon, was a contemporary of fellow Sandwich woodcarver Paul White, who was commissioned to make a replica of the 11-foot figurehead for the 1892 battleship USS Olympia and who’d written numerous books about wood carving. Hayden met White on a few occasions, but it was Amidon who had a direct influence on him. Amidon would give Hayden entire projects and soon Hayden became the lead carver at the business.

His interest in boatbuilding soon led him to Ballentine’s Boat Shop in Cataumet, Massachusetts, where he did the interior joinery for the restoration of Ariel II, a 46-foot power cruiser that the Herreshoff Manufacturing Company had built in 1931. Hayden had never done any boat carving, but when they wanted name boards on Ariel II’s pilothouse, the job fell to him. “That’s where it first started coming together for me,” he says. “When I was in college I was thinking of boats as giant sculptures, but at Ballentine’s I cut my teeth. I realized all that stuff ties together: boatbuilding, sculpture, carving.”

Just out of college, married and with children, he knew he wanted to build boats, so he moved his family to Maine. He did a short stint at Hinckley, but found it wasn’t his thing. “It was more production,” he says, “and I was into custom stuff.”

He joined BBY as a shipwright and continued to carve. He also started gold-leafing and name painting for the boatbuilders in the area, including Doug Hylan in Brooklin and John O’Donovan and Pat Dole in Searsport. When BBY completely rebuilt the 74-foot commuter yacht Aphrodite that the Purdy Boat Company had launched in 1937, Hayden carved the scrolls into her restored bow. “They cut the old scrolls right off the boat,” Hayden says. “I made a pattern of it and reproduced it on the new hull. When I worked at BBY there were 60 people. Boatbuilders by nature can adapt, but I was the only carver.”

Hayden spent 15 happy years at BBY. Soon after starting at the yard, he’d hung out his own shingle, Hayden Sign Company, but five years ago he decided to make that business a full-time endeavor. Like the ship carvers of old who would occupy themselves when there was no ship work by making signs for local merchants and carving interiors for homeowners, Hayden spends a fair amount of time painting and gold-leafing names on boats. “There are other people who do painting, but not carving, and not maritime wood carving,” he says. “It’s a real niche.”

One reason is that there are fewer wooden boats being built, but it’s also because American ships were never as ornate as the European ones. Ship carving in Britain was a highly specialized profession taught through a seven-year apprenticeship. “They used a classic European guild approach,” Hayden says, “and you could see that aesthetic. What they did is beautiful, but in New England it’s more a folk-art tradition. The people who lived on the waterfront scavenged wrecks. On Cape Cod, people would bring name boards back from salvaged ships. The local craftsmen would look at these fine European carvings and reproduce them. That is the tradition I sort of work in. When I teach maritime wood carving at the Wooden Boat School, it’s in this New England sense, as opposed to Europe and a traditional approach. The New England aesthetic is minimal, very puritanical,” Hayden says. “If you look at the Herreshoff aesthetic, it’s also very sparse. Herreshoff had sort of a factory mentality. They wanted to streamline everything.”

Most of the carving work Hayden does is incised letters and scrolls. That requires him to use a V-shaped chisel to give the carving what’s called a root. The technique was developed to allow the light to reflect off the gold leaf on one surface and then bounce onto and off the other one. “It’s kind of like the first neon sign,” Hayden says. “It makes everything pop.”

Hayden uses Swiss-made Pfeil chisels, which he says are considered the best, and which he also recommends to his students. He turned his mallets on his own lathe. One is an offcut of a laminated mahogany stem that he’d picked up off the floor of a boatyard and the heavier one is turned out of white oak.

He tries to use Honduran mahogany for his carvings because it’s rot-resistant and carves really well. African mahogany is now commonly used in boat building but because of its ribbon-grain it’s not ideal for carving. He also uses white pine, and he’s carved teak nameboards for Alec Brainerd at Rockport’s Artisan Boatworks. “He pretty much does all of the names on all the boats we store, build or maintain, here,” says Brainerd, “whether vinyl, painting, gold leafing or carving. Anything that involves the name of a boat, Reed’s the guy.”

Asked why he hires Hayden to hand carve a nameboard instead of using a router and computer, Brainerd doesn’t miss a beat. “It’s art,” he says. “Anything a computer generates is going to look like it was made by a computer. Reed brings the design elements and his layout skills. He can curve the name and he can follow the curve of the deck. There’s a lot of subtle stuff that I don’t even fully appreciate. The secret of my success is to surround myself with people who are smarter than I am, and Reed is one of those people.”

Down the street from Artisan Boatworks, Rockport Marine owner Sam Temple also praises Hayden’s abilities. The two men worked together at BBY, and Temple hired Hayden to rework the scrolls on the bulwark of Saphaedra, a 51-foot K. Aage Nielsen design that Rockport Marine was restoring.

Someone had redone the scrolls on the 1965 ketch, but not quite the way they should have been done. Hayden took some photographs of the scrolls and while looking at them with Temple, the maritime historian Maynard Bray happened to be in the Rockport Marine office. Bray mentioned that the original Saphaedra scrolls were in one of his books and Temple happened to have a copy of it on his shelf. Hayden overlaid the photos of the existing scrolls and the ones in the book on his computer, created a third version that had the spirit of the original, carved it, painted it and gold leafed it. “He’s up there on a staging plank, bouncing up and down, chipping away and talking to me about something entirely unrelated,” Temple says about Hayden. “I’m impressed as hell that he could pull that off.”

Hayden remembers that day, too. “Sam told me, ‘I have people who can do the design work, and I have people who can do the carving, but I don’t think I have anybody who has the guts to start hacking into a $20,000 toerail.’”

Hayden is glad he moved to Maine almost 20 years ago. “It’s been the best thing,” he says. “All of these people l’m doing business with are people I know personally. I just like the idea that I have a relationship with them.”

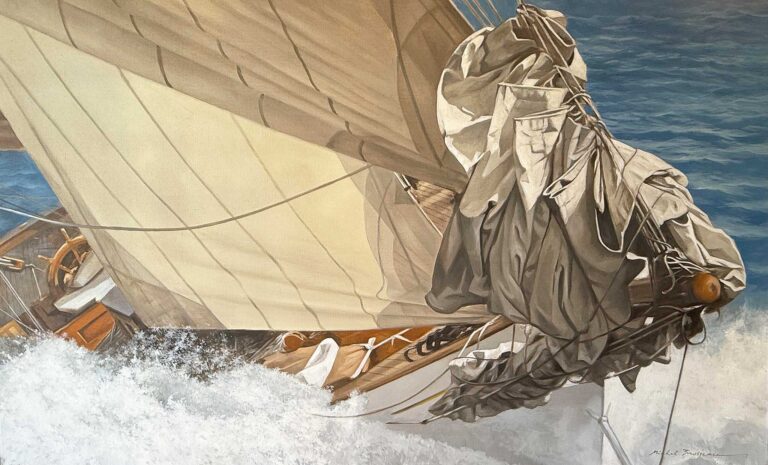

One of those people is Bray. While Hayden was making some woodcarving videos with the maritime historian, he saw some photos that Bray had donated to the Penobscot Marine Museum in Searsport. “I had been wanting to do boats underway, and I thought, ‘that’s the perfect thing.’ So, I called Maynard and the guys at the museum. I wanted to make sure I had their blessing.” He hopes to take 10 of the photos and turn them into large scale wood carvings and have a showing.

His interest in art remains strong. In 2020, he received his MFA in intermedia at the University of Maine at Orono and he is about to get his PhD.

“The art, the sign making, the boatbuilding, I’ve been doing it all along,” he says. “I always try to do everything, which is probably not the greatest habit, but at this point I have years and years of experience of carving. It’s my greatest skill. And it is what I’m most confident about.”

This article was originally published in the March 2022 issue.